Two weeks ago I started telling you about my OO Gauge Fixed Link Couplings, you can find the post here. In this week’s post I’m going to share with you the design and different types I’ll be making available and why.

As the name suggests these are fixed link couplings and can’t be uncoupled. They’re designed to allow strings of rolling stock to be coupled permanently in sets with the correct-looking couplings. This is ideal for exhibition layouts or block trains which don’t need to be shunted.

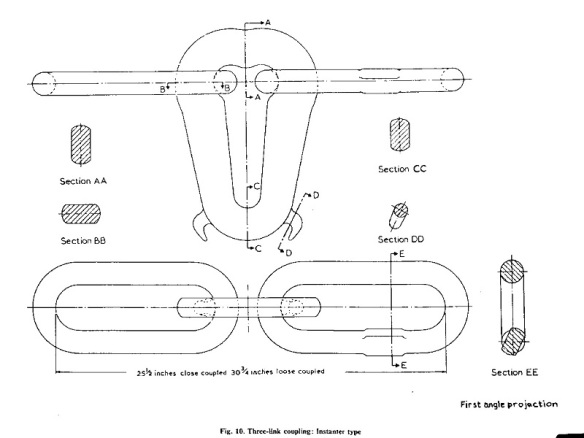

The two basic styles, as pictured below, are Instanter, shown in green and 3 link, shown in red.

The actual style of Instanter or 3 link is purely cosmetic as this simply forms a rigid fixed link between the NEM connection. Why did I do this instead of leaving the chain links loose? Well, if the links were loose it would alow the coupling to close up when a locomotive is pushing the rolling stock, but this would mean the loco will be pushing on the buffers. Unlike the real thing this doesn’t work very well on most ready-to-run OO rolling stock and tends to lead to derailment. Having the chains fused turns the coupling into a drawbar and as it’s centered on the rolling stock it allows long trains to be pushed without any issues. To fuse the chain links I have drawn a bulge making them a bit fatter where the links meet; this causes them to overlap and become one solid piece.

As I said above, making the connection into a solid drawbar gives the advantage of allowing the train to be pushed but what about going around curves? The NEM sockets do allow a bit of sideways movement but depending on which manufacturer will depend on how much. So I have designed in a flexible section at each end which allows for some more movement. This can be seen on the Instanter connector below.

As the coupling bends either to the left or right one of the gaps will open slightly. When the train is being pushed the gaps close equally keeping the force straight.

Below I have two brand new OO Bachmann covered hopper wagons linked with the coupling above.

As the trucks are twisted to the max, where the buffers touch, the NEM socket swivels as well as the flexible section in the coupling.

The different types, apart from Instanter and 3 link, refer to two variations in the NEM sockets. The first is length, or rather the distance the NEM socket is set back from the front of the rolling stock. Although the NEM standards specify the size and position of the socket, not all manufacturers have them in the same place. Length is also governed by the tightest radius curve on your layout. The tighter the radius the further apart the rolling stock needs to be before the buffers lock and cause a derailment. With some exhibition layouts which only have big radius curves my shortest couplings can be used.

The second is height, some NEM sockets are lower than others. To solve this I did an in-depth survey of all the main manufactures and determined that the issue could be overcome with three different shapes, which are all shown below.

The top one is simply a straight coupling. The second is a cranked coupling and the third is a step-up coupling. Below you can see the same two Bachmann hopper wagons with a straight Instanter fitted.

The Bachmann NEM socket is low and consequently so is the coupling. By using a step-up coupling it raises the Instanter.

The cranked coupling is designed to be used when connecting rolling stock from different manufactures. For instance, below are a Hornby and a Bachmann coal wagons. The Hornby NEM socket is higher than the Bachmann but using a cranked coupling solves the problem.

You many have also noticed the original plastic molded hook is still on the model above the coupling. My couplings technically are still lower than the real thing but doing it this way means you don’t have to modify your rolling stock if you don’t want to as the new couplings simply plug-in. I will also be offering an advanced range which raise the couplings to the corrected height but this will require the plastic molded hook to be cut off.

Next week I’ll share with you the full range of my OO Gauge Fixed Link Couplings as well as a way to judge which ones you need.

But my favorite section was the twin bridge across the river.

But my favorite section was the twin bridge across the river.

You must be logged in to post a comment.