As promised in my last post I have an exciting announcement to make this week. James’ Train Parts has been my passion since November 2013 when I first wrote about drawing a 3D printed shell for an EMD DD35 for N Scale. And I’ve done lots more since then. As well as all the 3D printed parts and things I’ve posted about here, I’ve also been regularly repairing trains and fitting sound decoders, but what many may not know is I’ve also been building layouts for customers.

However, this is a lot to do when you also have a full-time job! I’ve had a huge amount of support from taking my small one man business to a group of individuals who are a part of the model railway community and an essential part of the work I’ve been doing over the last year. Which leads to my big announcement…

In just two weeks’ time we’re turning a part-time hobby business into a full-time enterprise and following our dreams of filling our working days with model trains and railways. With continuing support over the last few years we’ve steadily built a small business providing layout design, construction, electronics and scenery, as well as servicing and repairing existing layouts and trains. With ever-increasing demand from a growing customer base now is the time to take the opportunity most just get to dream of, so here we go!

This blog will continue under the new business name, the old James’ Train Parts address will still work, and you’ll start to see more posts about the layout construction and work we do.

Thank you for your support in helping me get to this stage, the blog has been successful in ways I could never have imagined, and I look forward to sharing my next step with you all.

The

The

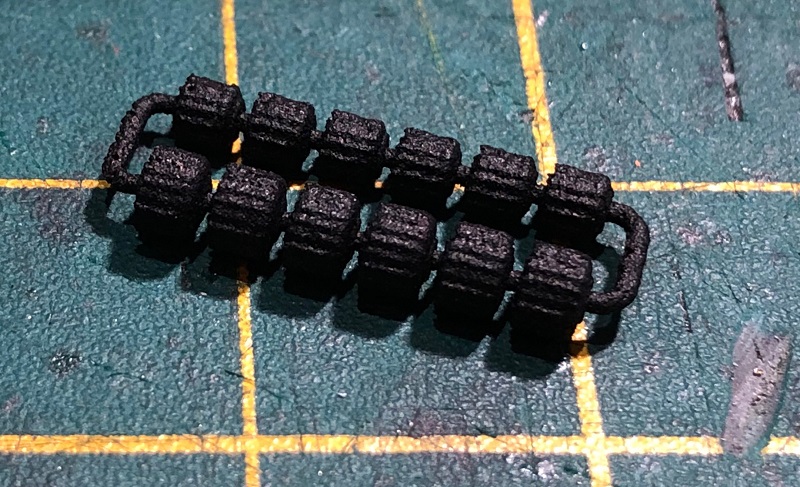

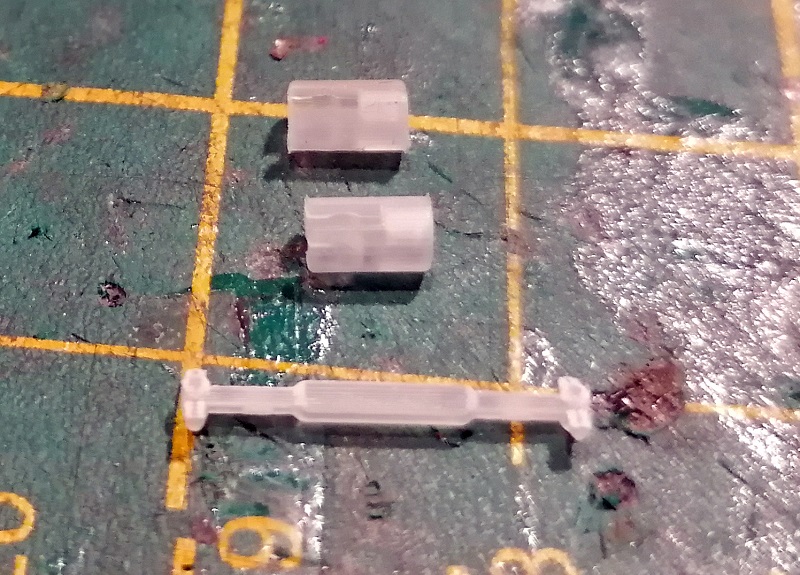

Speaking of Atlas models, the N Gauge diesels also suffer from cracked drive parts. The universal connecter inside the flywheel often cracks, leaving the locos underpowered. But new 3D printed parts are now available and you can read about them

Speaking of Atlas models, the N Gauge diesels also suffer from cracked drive parts. The universal connecter inside the flywheel often cracks, leaving the locos underpowered. But new 3D printed parts are now available and you can read about them

You must be logged in to post a comment.