This week, as promised, I’ve made the HO Baldwin RT-624 kits available to purchase. They’ve now passed all of my checks and had all the little improvements made.

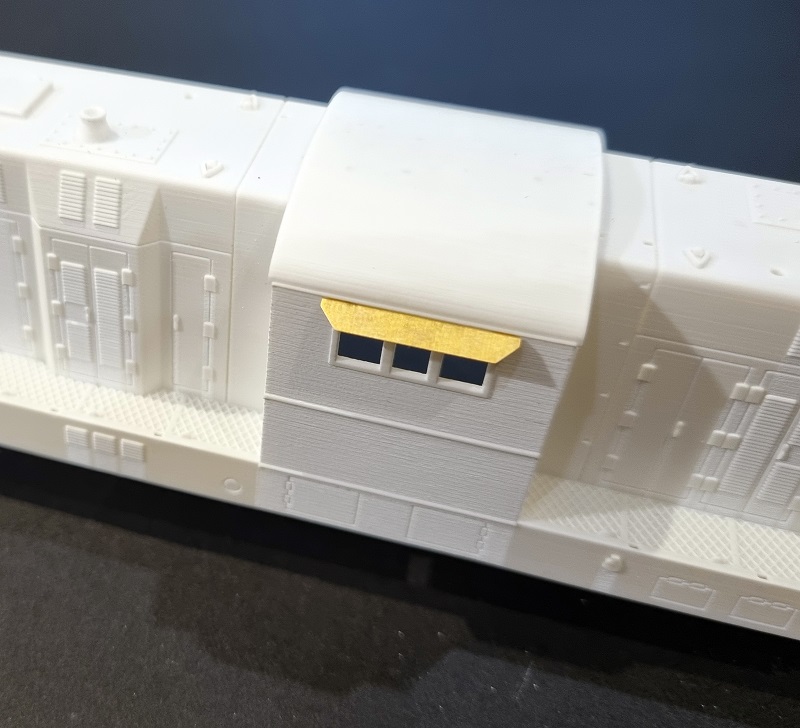

There are two kits available, and both look very smilier but there are differences. Below is the first version.

This kit is for the early Pennsylvania Railroad RT-624 locomotives with the Trainphone. The kit has three parts; the main 3D printed shell, 3D printed detail parts, and etched brass Additions. The 3D printed detail parts and etched brass are the same for both versions.

The second version is for the later Pennsylvania Railroad RT-624 locomotives without the Trainphone. It also has some body differences such as a different headlight position.

The donor chassis used for this model is a Bowser C-628 or C-630, the kit does not come with this.

Please also note that these locomotives have the correct asymmetric trucks but they’re facing the wrong way round. It will work but in order to make it look right you will need to rotate the trucks. As with my DT-6-6-2000 kit I developed a 3D printed kit for rotating the bowser trucks and re-using their side frames. (Bowser sell the correct side frames as spare parts if your donor chassis has the wrong ones).

All the parts are available from the links below;

Early PRR HO RT-624 Body Shell

3D Printed Detail Parts (For both versions)

Etched Brass Additions (For both versions)

3D Printed Truck Rotation Kit (DT-6-6-2000 Kit also for all RT-624 versions)

Commonwealth truck side frames are available from Bowser with their kit 96-603; it can also be used to upgrade an older Stewart Chassis to better pick up if that’s the one you have. It can be found at the bottom right of the Bowser page using the link below. (If these become hard to get let me know, I can make a 3D printed set of side frames available.)

https://www.bowser-trains.com/instructions.html

The couplings for this locomotive has been designed as Kadee #148 HO Scale 140-Series Whisker® Metal Couplers with Gearboxes – Universal – Medium (9/32″) Centerset Shank.

These locomotives have also been designed to receive powered Kadee couplings using Precimodels motors. To make the couplings powered you’ll need the Precimodels kit.

https://www.precimodels.com/en/

The last shell in the HO RT-624 range will be the single Minneapolis Northfield & Southern locomotive numbered Twenty-Five which I’ll soon have finished.

If you have any issue ordering or any questions please let me know. Ready-To-Run versions can be made on request if you prefer, please contact me via the contact page for a quote.

Now the kits are finished I’m going to paint up the two test prints. I have an ATSF DT6-6-2000 and an early PRR RT-624 which I think will look great, and I’ll share them with you once done.

You must be logged in to post a comment.