Over the last few weeks I have been drawing and designing a kit to make an N scale DT6-6-2000 using an Atlas C-628 or C-630 powered chassis. The test print has now been made and in this post I will share with you the results, the small changes I have made and where you can buy your own.

You can read more about the design in Part 1, Part 2 and Part 3 of the drawing process.

Straight out of the Shapeways box the DT6-6-2000 shell looked great. Even though it was covered in the normal waxy residue I could already see most of the detail, and nothing seemed to be damaged, badly printed or missing. To get the model ready for initial photos I simply washed the parts in warm soapy water. This still leaves a waxy residue on the parts and they can’t be painted yet, but as you can see from the pictures below it is enough to show you what it looks like.

Even though the parts haven’t been properly cleaned yet I couldn’t resist trying them out! First I looked at the truck side frames, and they fitted perfectly. All the little clips and catches on the Atlas power truck lined up with the printed side frame and it fitted together with a positive click. Below is a comparison showing the Atlas truck side frame on the left and the printed one clipped onto the power truck on the right.

From the under side you can see the clips and catches as well as the gear holes.

Having gone this far I had to try them both in the chassis and do a test run.

The chassis ran perfectly proving the side frames where not too tight on the axle ends and there wasn’t a clearance issue between the underside of the printed side frames and the rail tops etc.

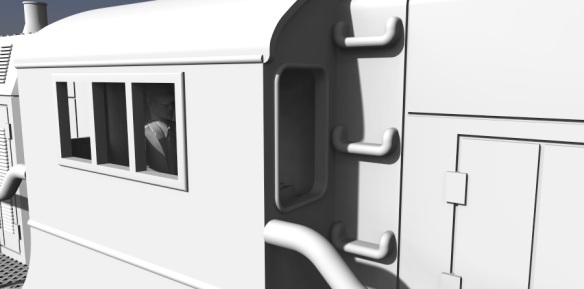

The detail on the actual shell is very crisp as you can see from the photos below showing the exhaust stack, lifting lugs and horns.

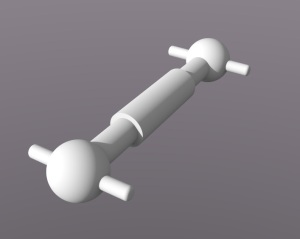

Even the uncoupling bar that runs across the top of the knuckle coupler has printed perfectly although it is very hard to see in the image below. When the FUD material is freshly printed and transparent like this it is very difficult to photograph and being wet with waxy residue doesn’t help!

Next I wanted to test fit the shell on to the chassis but to do that I needed to remove the handrails from inside the shell. As with my EMD DD35 kit I have printed the handrails fixed to the inside of the shell. This is firstly to protect them and secondly to avoid adding expensive material to the model in the form of a sprue. The handrails are mounted on cross braces that also hold the shell square as you can see below. Sometimes when a print run is finished the parts cool a little bit too quickly and thus can cause a little bit of distortion, so the braces help prevent that. If you get a printed model which has distorted you can read about how to fix it here.

I cut the handrails out using an X-Acto knife but I’d made the ends of the cross braces a little too big which made them hard to cut. I ended up pushing very hard which is not recommended with FUD as it can be a brittle. I have since reduced the ends of the cross braces which will make the hand rails much easier to cut out. All six hand rails come out in one piece as you can see below.

The shell was now ready to fit onto the chassis and it slid over the metal frame and located onto the metal lugs with ease. As one end of the chassis is higher than the other I added locating brackets inside the shell to sit on top of the chassis at the relevant heights; this means the shell will only fit on one way. In the photo below you can see the lower end is on the left.

With the shell test fitted the first thing I noticed was the trucks seemed very close to the triangular section next to the front steps. I was worried that this would prevent the trucks from turning but after doing several tests around a tight corner on my layout I discovered it was not close enough to touch but as a good measure I have moved the triangle away from the truck a little bit more. The locomotive trundled around my small yard quite happily as you can see below.

The last big check I wanted to make was the coupling pockets. The shell has been designed to receive Micro-Trains N scale body mount couplings in a pocket on the underside. There is a pilot hole ready for the mounting screw and a gap in the pilot to allow the coupling to poke through. As the pilot hole was full of wax residue, and slightly smaller than the screw diameter by design I drilled out the hole using a #62 tap drill from Micro-trains and taped it using the 00-90 tap from the same tool set. Once I had assembled the Micro-trains body mount coupler I pushed the screw through the coupler. The standard screw that comes with the body mount couplers is two long for the shell, it would protrude up through the walkway if left as it is, so I cut it short with a pair of side snips. Please use safety goggles if you are going to do this as the ends fly all over the place. I left about 2mm (0.078″) of the screw protruding from the coupling and inserted it into the pocket. The screw lined up perfectly with the hole and I was able to do them up. As FUD is a plastic, don’t over tighten the screw or it will pull out and ruin the thread in the shell. Also if it’s too tight it will prevent the coupler from working properly. Once both were installed I was able to check their heights and see if they functioned correctly. I did this using a Micro-Trains N scale coupler height gauge as pictured below.

The high was perfect.

And finally, as you may recall, I also included an engineer for the cab. and here he is.

He is very small, and this photo doesn’t do him justice. The only issue I had was not with him but with my design. I found that even though I had put locating locating lugs in the shell to fix him in the right place it would be very difficut to do as there is nothing to get hold of him by. So I have now added a tab on the underside so you can grab him with a pair of tweezers.

Now all the checks and tests are complete I’m happy to make the kit available to buy in several options such as unpowered dummies and with or without truck side frames. You can find them all on the new website page here.

In a future post I will share how my DT6-6-2000 looks painted up in Santa Fe colors transferring freight from one yard to another.

You must be logged in to post a comment.