Two weeks ago I shared with you the first part of this post about adding working lights to some of my HO Scale Union Pacific excursion train water tenders. You can find the post here. In this week’s post I will share with you the next step.

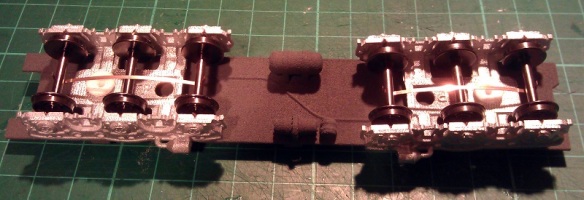

At the end of the previous post I had gotten as far as adding the power pickups to the 3D printed trucks and installing the DCC decoder as you can see in the image below.

The original idea was to simply hook the white and blue wires up to an LED which was mounted inside the tender shell. Below you can see the chassis with the LED fitted and working. I have also added some weight to the chassis which greatly improves the power pickup. The weight is off-center to avoid the baffle in the center of the tender shell.

However upon testing the system I discovered a small problem. Because the DCC decoder I had selected is a function only decoder, that is to say it has no motor controls, it works well when run on a DCC layout but will not function properly on a DC layout. This is because a function only decoder doesn’t recognise direction. A regular DCC decoder will recognise forwards and backwards, switching on the relevant wires to turn on the correct lights. A function only decoder will simply respond to function key commands. In the case of the Digitrax TL1 that I have used; F1 will turn the white wire on and off. When the tender is running on a DCC layout the operator can consist the tender with the locomotive, then when they push the F1 button the tender headlight will come on as required. But under DC control the headlight will only continue to do whatever the last command was under DCC control. For example if the light was lit when running on DCC, the light will remain lit in DC irrelevant of direction and cannot be turned off.

As these two tenders are wanted for both DC and DCC operation I will need to come up with another solution. One option would be to replace the function only decoder with a full motor decoder. That way it would respond to directional control in both DC and DCC but there would still be the risk of it being removed from the DCC layout with the light off, then it would not work on the DC layout. Also full motor decoders are more expensive. A simpler option that I have decided to use is to add a switch to the underside of the tender chassis which will allow the operator to switch the tender from DCC to DC control. That way the function decoders that have already be purchased will not be wasted.

The type of switch required is a double pole double throw toggle switch. Double pole means that it can switch two separate wires at the same time; in this case positive and negative. Double throw means rather than simply on and off it switches each pole from one input to another; in this case DCC power to DC power.

As I described in part one of this post each truck picks up power from a different rail. Irrelevant to whether it is a DCC or DC layout, one rail is treated as positive and one as negative. At this point the two power wires need to be divided so that power goes to the DCC decoder and to one side of the switch. The output from the DCC decoder will then go to the other side of the switch. From the middle of the switch will come the two wires that feed the LED. When the switch is set to the DCC side the system will operate as it did before, responding to the F1 command on a DCC system. With the switch set to the DC side the power will bypass the DCC decoder and go directly into the LED. Because and LED is a diode, which means power can only pass through in one direction, the light will only come on when the train is moving in the direction the light is facing.

To find the right DPDT toggle switch I had to look at the available space on the chassis. Although there is a lot of room inside the tender itself, there is not a lot under the chassis and I did not want something huge sticking out that looked unsightly or might foul things like turnouts or crossings. A standard DPDT toggle switche would be simply too big, as would a sub miniature one; but an ultra miniature one would work well. Below is an ultra miniature switch next to a miniature one.

The switch will be mounted to one side near the center of the chassis. That way there is no chance of it interfering with the swing of the trucks.

Although this switch is very small the lever that projects out is still too long so I cut about two-thirds of this off with a disc cutting tool and filed the edges to remove any sharp bits. It is now fairly inconspicuous under the chassis.

A small corner of the air tank also had to be cut off to allow the toggle switch nut to be fitted but this will not be visible when the tender is on the track. The switch will also be painted gray to match the chassis helping it blend in.

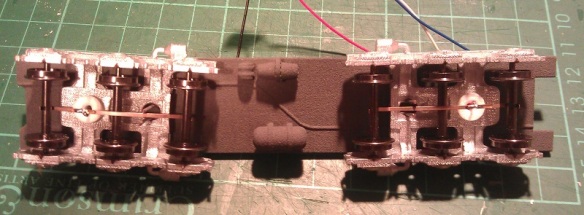

Next the switch needs to be wired up. The red and black wires from the trucks go to the two terminals on the far side. The DCC decoder is then also connected to the same terminals. This is where the power is split. The output from the DCC decoder, the white and blue wires, are connected to the near side terminals. With DCC decoders the blue wire is the common function wire which is positive. Therefore it needs to be connected to the switch on the same side or pole as the red wire. If the light was powered by a regular bulb this would not make a difference but because LEDs are diodes the polarity of the wires is important.

Next the LED wires are connected to the two center terminals as shown below.

Often DPDT toggle switches have three positions, the middle being off. This can be useful as it ensures there is no chance of a short as the switch is thrown. However the ultra miniature switches only have two positions but as the tender needs to be removed from the track to throw the switch this is not a problem.

The LED I am using is a 2mm lighthouse style with a warm white color. Regular white LEDs are often too bright and give a very cold light. I should also point out that it is necessary to use a resistor with every LED otherwise they will draw too much power and blow immediately. Below is a comparison between an ordinary 5mm LED and the 2mm lighthouse LED.

The light these warm white LEDs give off is perfect for recreating locomotive headlights as you can see from the images below. For these photos the headlight has not been properly secured so it is pointing up a bit. I need to finish the shell and add all the decals before I can fix the headlight on properly.

Taking photographs in the dark is not the easiest thing to do but below is a shot of the tender in low light, as you can see the headlight gives a nice beam.

In next week’s post I will share with you the final stage of fitting the LED into the shell. I will have also finished the shells, completing the tenders.

You must be logged in to post a comment.