A few fellow modellers and I are building some new N Scale modules for our Solent Summit modular layout. Several of these modules will require chain link fences and a discussion about what to use led me to produce my own N Scale etched chain link fencing products.

*These will be available for regular purchase in two weeks but I have an introductory offer for this product available this week only. Please see the end of the post for details.*

For the modules we are building there are three main types of chain link fence needed. Type 1 is a basic straight 10 foot long and 6 foot high section with 3 lines of barbed wire on top. Type 2 is the same panel as Type 1 but includes a small personnel gate. Type 3 is a large pair of access gates, again with the barbed wire on top. A 4th type was also discussed that did not have the barbed wire on top but it was decided that the existing barbed wire could easily be cut off.

The fence style is a typical configuration for chain link fences; tubular post and top cross rails for support and close pattern mesh. Here is a link to a typical example, and another here. Both from United Fence of Hattiesburg.

As always with my designs the process starts with 3D drawing or modelling, in this case it was a simple matter of drawing the different sections of fence as you can see below. The first and third sections from the left are standard panels. The second has the personnel door. The forth and seventh section include a diagonal brace to support the gate post. And the fifth and sixth sections are the actual gates giving a 20 foot opening.

Although 3D printing is suitable for constructing modelling components, for this fencing I am using metal etching. This has many advantages; etched metal components are strong and can be very thin. As this fencing is for N Scale at 1:160 the actual chain links will need to be thin to be believable. Although most of my etched metal parts to date have been made from brass the fencing will be made from stainless steel. Firstly this is because it will already be the right colour and will not need any painting. Secondly stainless steel is a lot stronger than brass. This means the base metal can be a lot thinner without losing its strength. Using this to my advantage I have been able to select a very thin metal, 5 thou thick, and also half etch the actual chain link section. This means the fence part is only 2.5 thou thick and appears to run behind the post just like the original.

With the design agreed upon the sections of fencing were laid out in a practical configuration. This took the form of a one hundred foot length of fencing. Each length will be in its own etched fret. A fret is an etched section of metal that has the final part and its supporting frame. Three different styles of fret make up one sheet as you can see below. The first six frets are all Type 1 fencing consisting of ten regular panels. The next three frets are Type 2 which is also ten regular panels but every fifth panel has a personnel gate. The last two frets are the Type 3 with two sets of large access gates and two regular panels making up the one hundred foot of fencing.

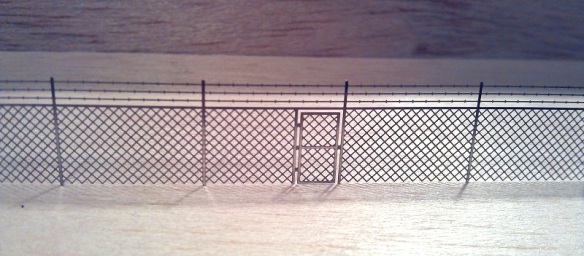

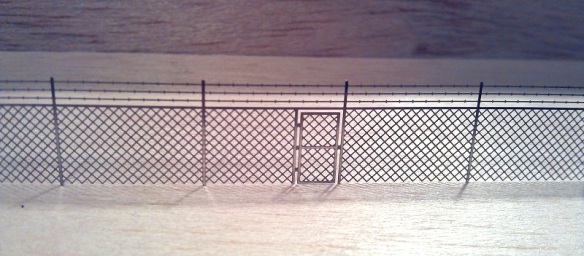

In total a whole sheet has 1100 foot of fencing on it. To show you how easy the fencing is to work with I have cut a Type 2 fret out of this sheet as you can see below. This is how a fret will normally be delivered unless you buy a whole sheet.

Zooming in closer you can see that the chain link is thinner than the posts.

The one hundred foot fence is fixed into the fret at six points with tabs; you can see two on the left of the photo above. These have been half etched where the tab connects to the fence so they can easily be cut with a craft knife.

The personnel gates have three hinges on one side and a lock on the other also represented by a half etched section.

To give you an idea of the size of the fret; here it is alongside a 4-8-2 steam locomotive.

Cutting the fence from the fret simply requires six cuts with a craft knife through the tabs as mentioned above. As you can see in the image below each post protrudes down past the bottom of the chain links. This is to allow a good fixing into your layout.

To help position the fencing I have included holes along the top of the fret which line up with the post. I have used a standard sewing needle to position the first post hole as shown below.

Then, without removing the needle, I used a second needle to mark out the other holes. Keeping the first needle in the base board stops the fret from sliding and losing its position. If your base board is made from a very hard material a small drill can also be used.

Once all the holes have been marked I removed the fret and increased the holes slightly by pushing the needle in a bit further. Then I simply offered the fence section up to the holes and starting at one end lowered the posts into the holes.

The fence is very stable and, assuming the holes are deep enough, the mesh will rest on the ground. Below is the installed fence again with big 4-8-2 behind it.

The steam locomotive is quite large so to show you that the fence is the correct size, below is a shot with the fence and an N Scale X-Act ruler. The top bar of the fence is six feet high and the barbed wire post project up another two feet.

As I said before the personnel gates and large accesses gates have half etched hinges and locks. The locks can easily be cut with your craft knife and the gates can be opened as shown below,

Quite often the barbwire sections at the top of these fences are bent over at an angle; this can easily be replicated. I used a pair of flat end tweezers to bend each post top over and the barbwire went with them.

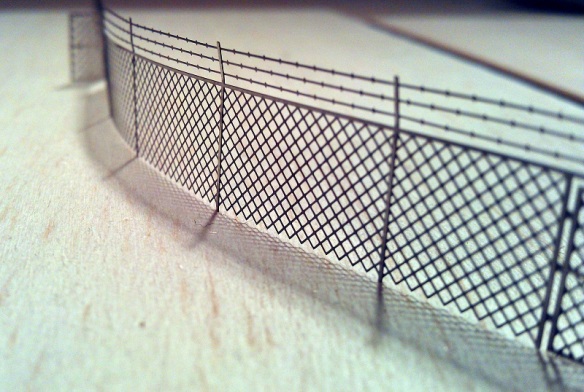

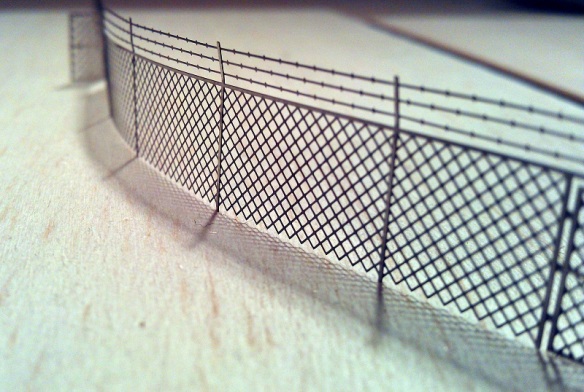

Not all fences are straight so using the holes on the fret again I put a needle into the last hole on the straight line then rotated the fret around it. I then marked the next hole.

Leapfrogging the needles and rotating the fret each time will give a curve with correctly spaced post holes.

The fence section then drops back into the holes.

The fence is surprisingly strong which will help in the event it is knocked on the layout. Below is a photo showing a Micro-trains coupling checker block resting on the fence. The block is quite heavy, for N scale, and only the barbwire flexed a bit, the fencing didn’t move. Even when the stainless steel fencing is loose it is still considerably stronger than brass. Also unlike details like handrails the mesh structure is a strong pattern even though its is thin.

It is very easy to see how quickly a scene can be made with this fencing.

The large access gates are installed in the same way except there is no post between the gates.

As well as using these fences on our modules I am also going to make them available to buy. Please note that the £ to $ conversion rate is subject to change, and the base currency is £ GBP.

Typically each fret, 100 foot of fencing will cost £4.00 GBP ($5.90 USD) plus P&P.

However as this is a new product I will be offering it at an introductory price £3.00 GBP ($4.50 USD) plus P&P per fret or £30.00 GBP ($44.00 USD) plus P&P for a whole sheet, 1100 feet of fencing.

This offer is only available until 22.00 EST on Sunday the 19th April 2015.

I will be ordering my stock on the 20th of April 2015 and will be shipping orders out on or before the following week.

Please contact me though the contact page or directly at jamestrainparts@yahoo.co.uk if you are interested in any chain link fencing and I can confirm P&P and details.

Next week I will be sharing with you some more development with 3D printing and some advancements in higher quality 3D printing.

You must be logged in to post a comment.